PVC Window Door Profiles Seamless Corner Welding Machine

Brand :Glorious Machinery

Product origin :China

Delivery time :15 Days

Supply capacity :10 Sets/Month

This machine is designed to deliver flawless and seamless corner welds, setting a new standard in precision and aesthetics for your PVC profiles.✨

✅ Seamless Perfection: Our PVC Seamless Corner Welding Machine achieve seamless corner welds, ensuring superior finish for your PVC window and door frames.

✅ Advanced Welding Technology: This machine creates smooth corner joints, eliminating visible seams for a high-end, professional appearance.

✅ Efficient Production: Boost your production efficiency with the seamless welding capability of our machine.

✅ User-Friendly Interface: Equipped with an intuitive user interface, streamline your operations and enhance productivity.

✅ Reliable and Durable: Built with quality materials and advanced welding technology, ensuring a long service life for your production needs.

ABOUT US

COMPANY INFORMATION

Jinan Glorious Machinery Co., Ltd is a window and door manufacturing machine industry research and development, design, production, sales, service as one of the integrated company.

The company has more than 10 years of machine research and development experience, has a professional R & D team and large production workshop, its strong machining capacity, can meet the customer's various machine processing needs.

The main products are: PVC/ aluminum window door processing machine, curtain wall manufacturing machine, thermal insulation composite aluminum profile processing machine, insulating glass manufacturing machine, etc.

COMPANY ADVANTAGE

Jinan Glorious Machinery Co., Ltd in strict accordance with industry standards and export standards organization production. The excellent quality and excellent performance of the machine have been widely recognized by customers. At the same time, the company continues to increase investment in product research and development to enhance the core competitive advantage of the products.

The company takes the needs of customers as the focus, our engineers combined with the actual demand of the market and the actual problems encountered in the production, on the basis of the original machine constantly improve, perfect, can better meet the needs of the customer's new products.

At present, the company's machines have been well praised in the international market.

OUR ADVANTAGE

QUALITY

100% reponsible for the quality

From production to sales

25 YEARS

25 years for window machines

Professional machine experience

SERVICE

Provide professional after-sales service, timely reply and solve customer problems.

OEM / ODM

Provide brand new machines

Customized are acceptable

MACHINE DETAIL

PVC Window Door Profiles Seamless Corner Welding Machine

This machine is a special equipment for welding plastic doors and Windows, it has 1, 2, 3, 4 a total of four heads. The four heads can be operated jointly or separately. It is a necessary equipment for the production of colored plastic doors and Windows, and the equipment can complete the welding process of most of the plastic steel doors and Windows on the market. Single point, two points, three points, four points any combination of welding.

Very suitable for welding color (including film, transfer, two-color co-extrusion, spraying) and other profiles welding. After the welding is completed, the welding distillation is cleaned at one time, and the size of the welding gap can be strictly controlled, so the surface welding is very beautiful and high-grade after the welding of the color profile.

| Input Voltage | 380V 50Hz | Welding Profile Range | Min:450mm MAX:4500mm |

| Machine Molds | WFH-4-5MF | Welding Profile Height | H=20~120mm W=120mm |

| Input Power | 4.5KW | Outline Dimension | 5300×1200×1750mm |

| Working Pressure | P=0.5~0.8Mpa | Weight | 2000KG |

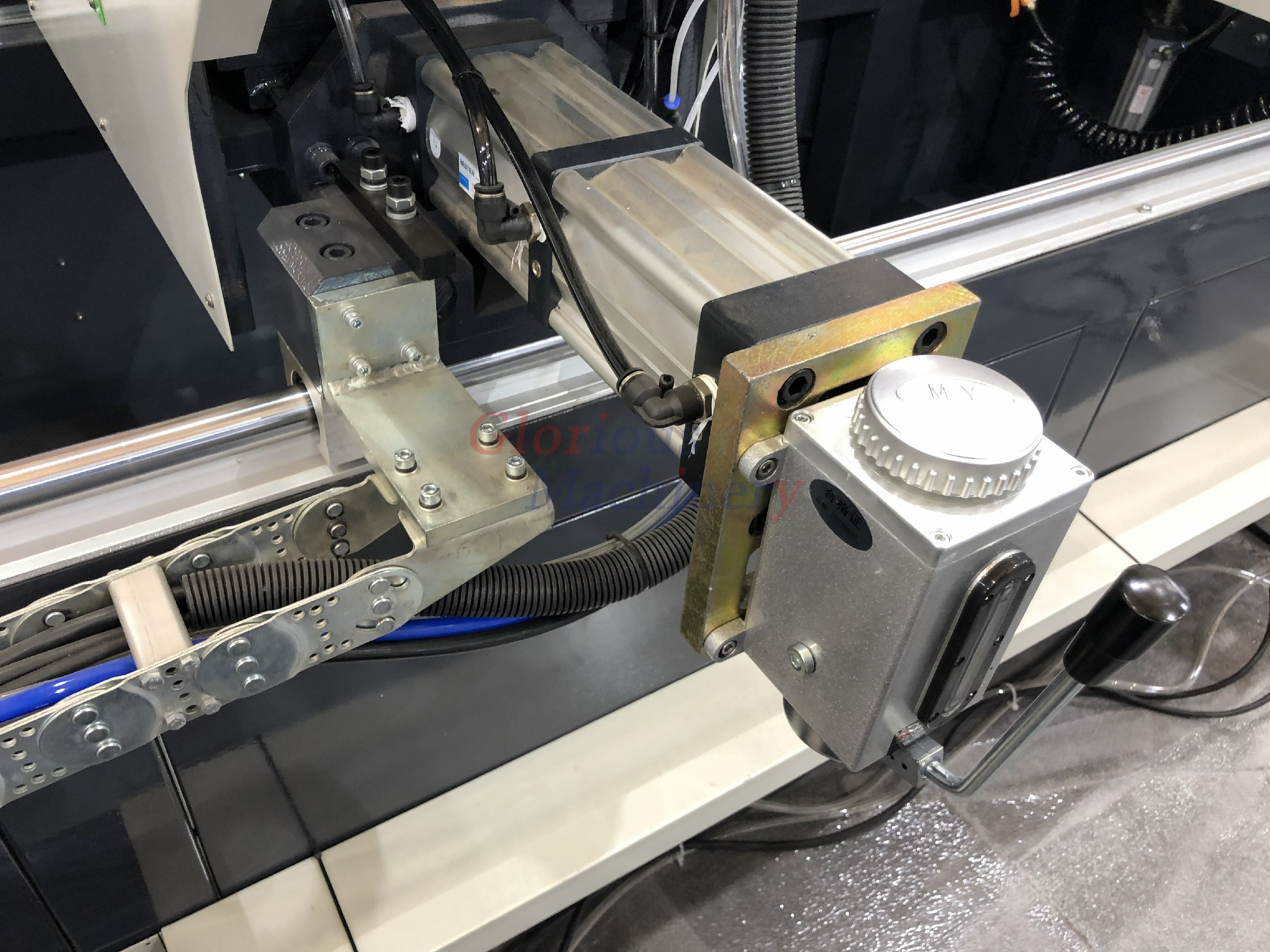

Special Horizontal Cleaning Knife

Seamless cutters are developed and processed through the release processand quenching process.

It using proprietary technology that can bekept level at all times.

High Quality Cylinder

The cylinder that drives seamless cutters adopts a double-layer structure with more stable power, longer life and higher accuracy.

Independent Compression Device

Independent compression device can better hold the profile.

To ensure that the longer profile will not occur displacement, and in the welding of the profile will not return.

Precision Square Track

The tracks in the nose are all imported square tracks. which ensures high accuracy There are 12 square guidesin one nose.

OTHER RELATED MACHINES

OUR FACTORY

OUR CUSTOMERS

CONTACT US

We are manufacturer and trading (integration)...more