PVC Profile Five Axis Corner Cleaning Machine

Brand :Glorious Machinery

Product origin :CHINA

Delivery time :10

Supply capacity :100SETS/MONTH

Product details:

Features:

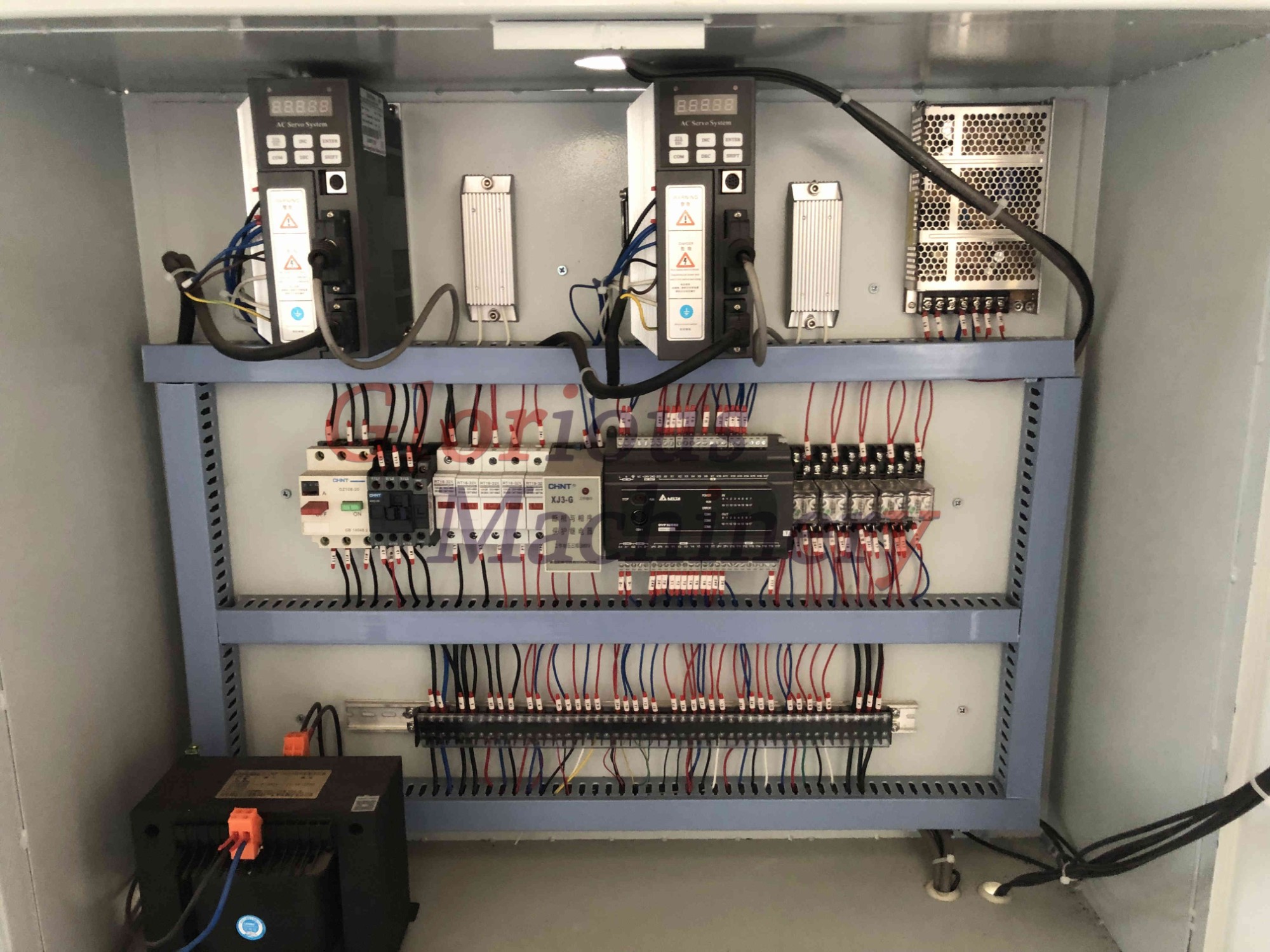

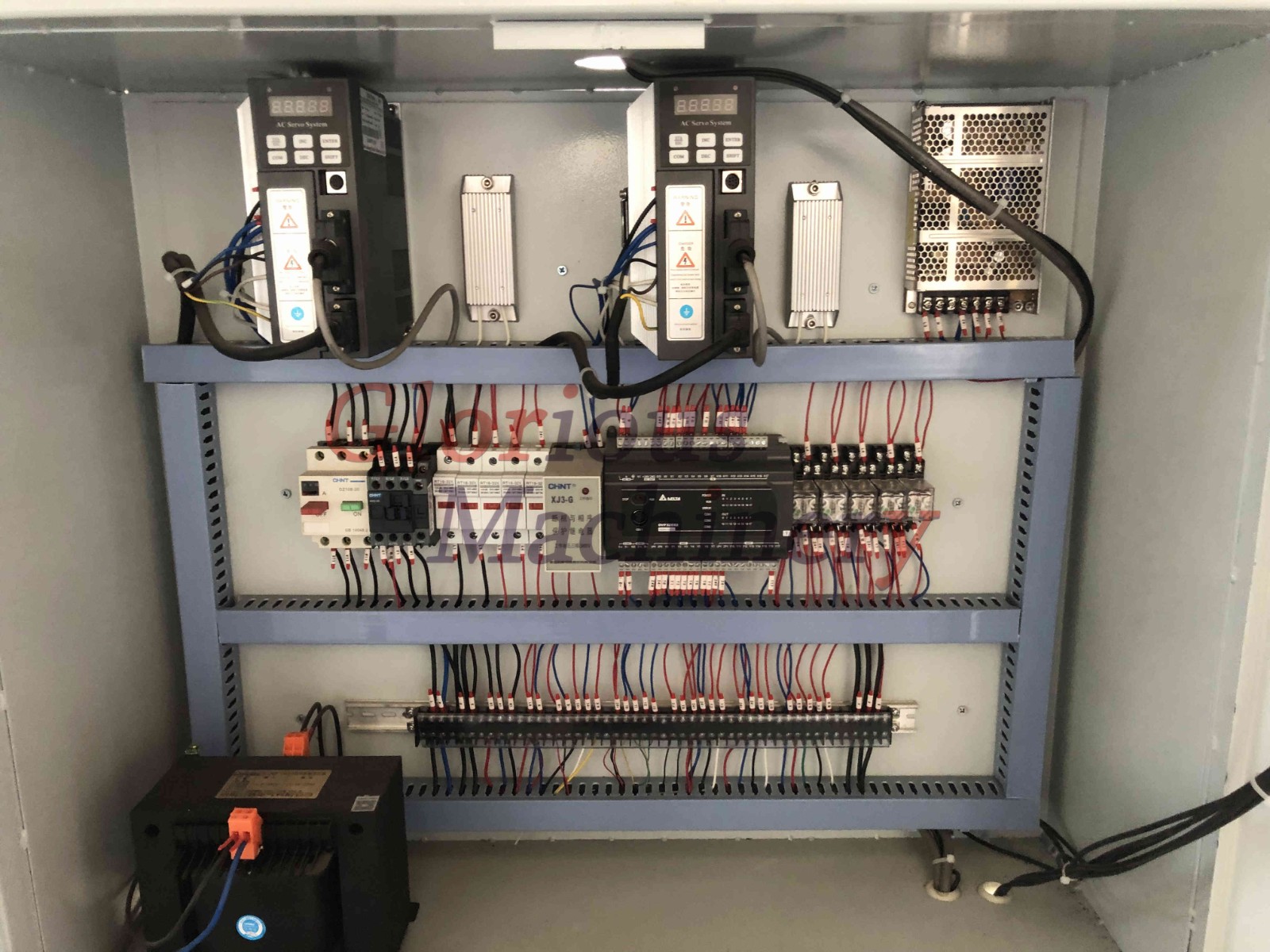

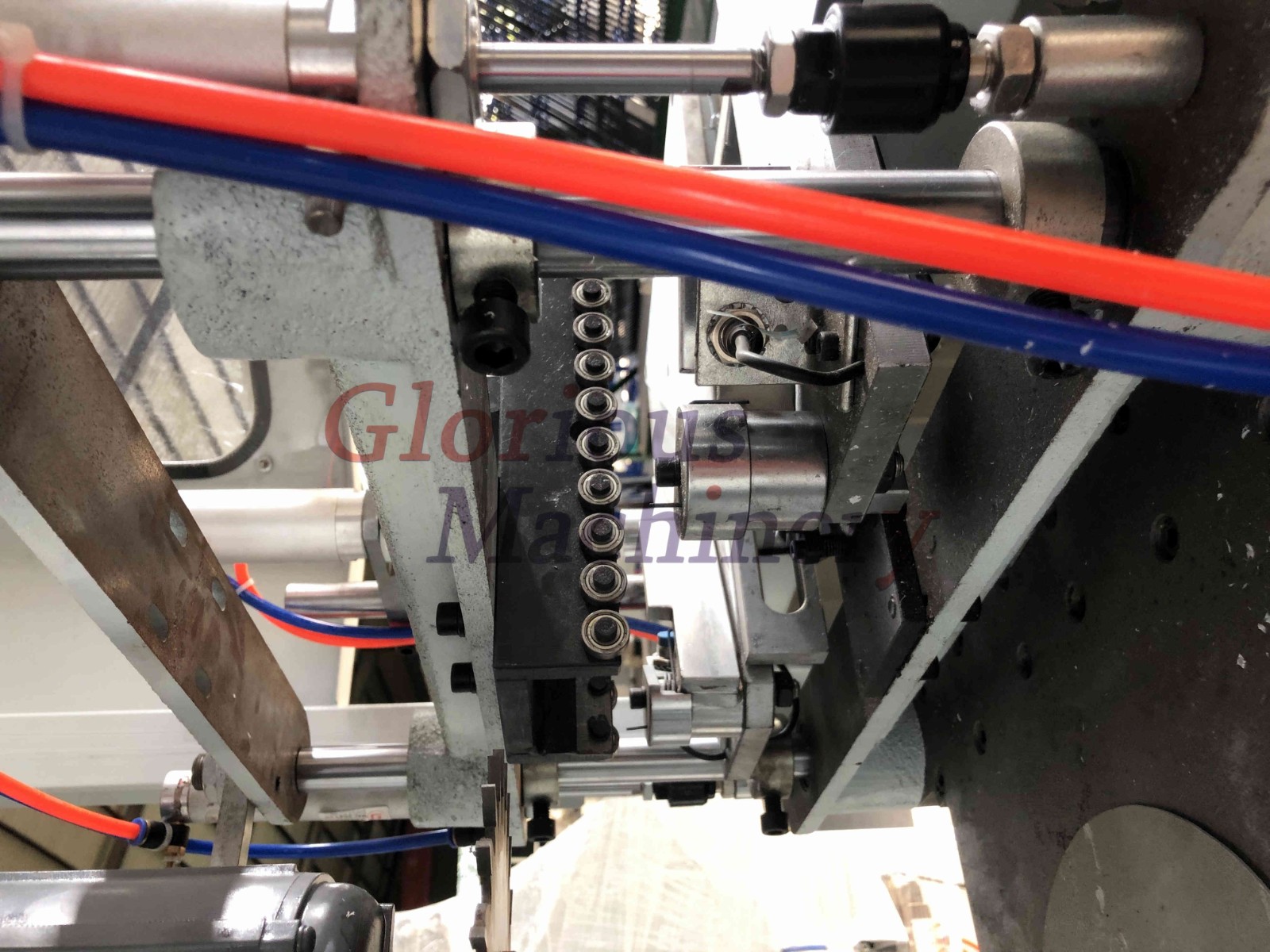

The machine adopts an imported Numerical Control System, which can set up a two-dimension process program according to a different profile. The machine can set up and store more than 100 sets of a processing programs. The tray-milling cutter can mill the external corner of the PVC door and window along the two-dimension track. With the upper and the lower vertical cutters, the machine can clean the grooves of the airproof bar and the unwanted welding tumor on the internal and the external flat slot at the same time or separately. And at the same time, it can clean the upper and the lower flat welding slot with the upper and the lower vertical cutters. Further, the needed number can be keyed in the spot situation, the processing program can be corrected based on the spot situation, so welding seam with error can be cleaned up efficiently. The machine has a character such as convenient adjustment, high automation, etc. The machine is a multifunction corner-cleaning machine for PVC door and window, which centralizes numerical control, pneumatic drive, and machinery technology together. It is with high efficiency, multifunction and stable, reliable quality and is the ideal machine for mass batch production of various profiles.

Parameter:

| Input Voltage | 380V/50Hz |

| Input Power | 2.0Kw |

| Operation Air Pressure | 0.5~0.8MPa |

| Air Consumption | 200L/min |

| Processing Hight | 30~120mm |

| Processing Width | 30~120mm |

| Speed | 2800r/min |

| Dimension | 2890*2780*2120mm |

| Weight | 700Kg |

We are manufacturer and trading (integration)...more