- Home

- >

- News

- >

- Technical Article

- >

- Threading machine and compound machine maintenance knowledge

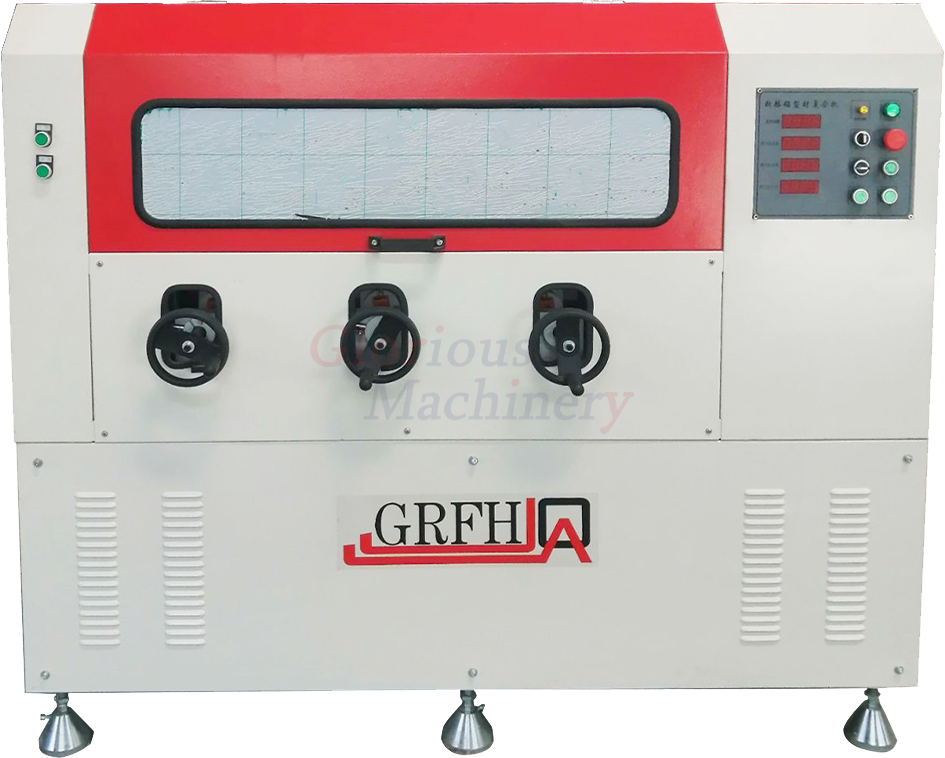

Threading machine and compound machine maintenance knowledge

1. Keep the equipment clean and free of debris, and perform hygienic work well.

2. Ensure that the circuit is smooth and there are no missing items. The neutral and live wires are not short-circuited, the wiring is good, and the electrical components are intact. Check the electrical circuit frequently.

3. The open-tooth cutterhead and pressure cutterhead are used normally without defects or deformation.

4. Use machines and equipment according to operating procedures and do not use them in violation of regulations.

5. The mechanical moving parts should be regularly filled with lubricating oil to avoid working without lubrication for a long time.

6. Comprehensive guarantee and maintenance of daily maintenance, regular maintenance, regular inspection and accuracy inspection.

7. Neat, clean, solid, lubricated, anti-corrosion, etc. work content, work methods, tools and materials used, standards met and precautions.

8. Solve problems in time when problems are discovered, and do not use machines while working while sick.

9. The air path part ensures that there is no air leakage, the air path is smooth and unobstructed, and the air path system is always lubricated and free of foreign matter.

The use and maintenance of the strip-threading machine is very important. If it is maintained, the quality of the products produced will be guaranteed and the accuracy will be high, and the life of the machine will be greatly extended. Therefore, it is very important to maintain the strip-threading machine well.